This entry is also available in: Russian Chinese (Traditional)

Motorworld’s newspaper №84

It is no accident that the noble particle Rex (‘Tsar’ in Latin) is a part of the name of the German brand Horex. Except the ‘King’ was tinned… But let’s start from the beginning.

At the end of World War I, German aircraft manufacturers were on the edge of an abyss – Germany was forbidden to develop aviation. But, as always happens in the years of devastation, the profits of food producers went through the roof. Because of the inflation, it was useless to keep money in the bank, so, in 1920, Friedrich Kleeman, financial director and co-owner of the prosperous Rex Konservenglas Gesellschaft, canned food company, acquired a controlling stake in the engine company Columbus Motorenbau AG. Columbus, which was making aircraft engines during the First World War. Under the new management, the company began with more prosaic work – producing Gnom engines for bicycles.

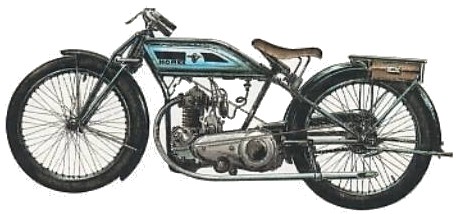

First Horex motorcycle, 250 cc OHV engine

Motorcycle Horex made after produced after the merger with Columbus

Sons are often more ambitious than fathers, and Fritz Clement, son of Frederick, confirmed the rule. Can’t a company that made aircraft engines make a motorcycle engine? Thus, in 1923, the first Horex motorcycle with a 250-cc OHV engine appeared. The name of the motorcycle was formed from two syllables: “Ho” – from the city of Bad Homburg, where the factory was located, “Rex” – from the brand of canned food. The sales went so well that in 1925 the two companies merged, although motorcycles were still sold under the brand name Horex, and engines, which were used by other German motorcycle companies – under the Columbus brand name.

It’s interesting that the production of the new conglomerate was marked by clear English influence: single-cylinder 4-stroke engines with a vertical cylinder arrangement had a chain drive to the gearbox. In the 1920s, the company acquired a license for the production of English Sturmey-Archer engines. It was continued by a talented designer Hermann Reeb, who from 1929 headed the design department.

Soon Reeb decided to develop a motorcycle with a larger engine capacity. He chose a completely unusual for that time layout: two parallel cylinders. This layout was not something completely new but was almost never used for road bikes (racing motorcycles Peugeot used this scheme with great success in the early ’20s). The designers were confused by the large overall width of this engine, its unbalance, and, most importantly, the poor cooling of closely standing cylinders. Only in the second half of the 1930s, the parallel-twin became popular, with the help of the creator of the legendary Triumph Speed Twin, Edward Turner, – but Reeb was ahead of him for almost five years (more info in the article about Triumph Tiger “T100”).

Hermann Reeb began developing a parallel twin on his own initiative in 1931, and only by Christmas 1932 showed his invention to his boss, Fritz Kleeman. It wasn’t the best time for the project: the economic crisis and the echo of the Great Depression could not promise good sales for expensive motorcycles. But in the spring of 1933, the market suddenly revived, and Kleeman gave permission for launching the novelty in mass production.

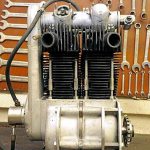

New Horex entered the market in two versions: the S6 (600cc, 24 hp) and the S8 (800cc, 30 hp). Both engines had the same stroke – 90 mm, differing in the diameter of the cylinder: 65 mm for the 600cc version and 75 mm for the 800cc version. Otherwise, the design of the two models was identical. On a light-alloy crankcase, Reeb vertically placed two cast-iron cylinders, with a large gap between them for better cooling. The cylinders and their heads (also made of cast iron) were attached to the crankcase with long studs (four for each cylinder). The crankshaft had a composite structure with three main bearings, the middle was installed in a special aluminum plate. Both connecting rod journals were on the same axis. The firing order is offset, so that cylinder 2 fires 360 degrees after cylinder 1, and 360 degrees later cylinder 1 fires again at 720 total degrees, the beginning of another four-stroke cycle.

The upper camshaft was driven by a chain in an aluminum casing. For better cooling, Reeb left a large gap between this casing and the cylinder. A big innovation for that time was a fully enclosed camshaft: it was usually open on OHV engines of that time. Hermann used a dry-type lubrication system, but at the same time built a 2.25-liter oil tank into the crankcase. Fears that this will cause overheating of the oil were in vain: tests by Das Motorrad magazine showed that its temperature didn’t rise above 60º. The engine was powered by two Amal carburetors.

On the right side of the crankshaft, there were two chains: one driven the upper camshaft, the other – magdyno and oil pump. On the left side, a two-row chain transmitted torque from the engine to a separate four-speed gearbox from Munich Hurth company.

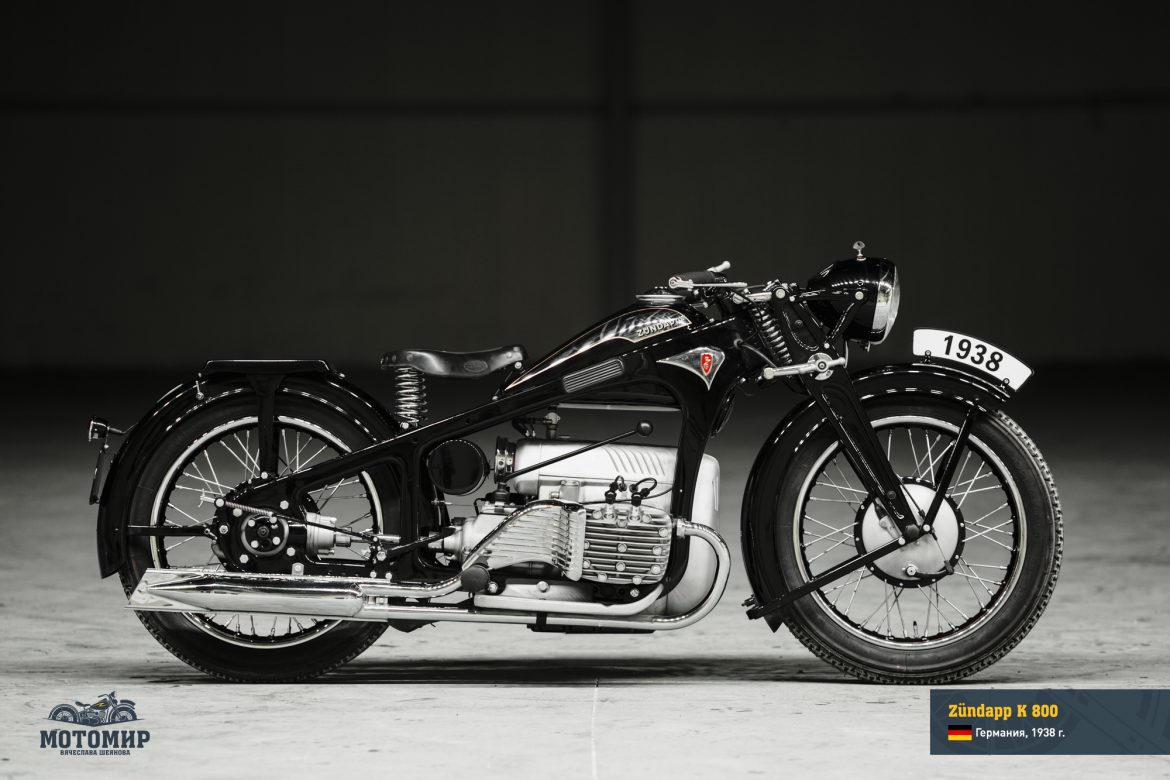

Zündapp K 800 from the collection «Motorworld by V.Sheynov»

A newly reinforced frame was developed for the leader of the model range. In general, the running gear was typical for those times: the front parallelogram fork, rigid rear suspension, and drum brakes on spoked wheels.

The Horex S6 cost 1,480 Reichsmark, the S8 model – 1,570 Reichsmark. At the same time, the debuted four-cylinder Zündapp K 800 was worth 1,550 Reichsmark. As Fritz Kleeman feared, the high price led to very limited demand. Production of the two-cylinder Horex lasted only two years, during which time 82 copies of S6 and 96 copies of S8 were sold. At the same time, Reeb had to deal with the “childhood illnesses” of the engine. On motorcycles of the final series, the diameter of studs, which attached the cylinders to the crankcase, was increased from 8 to 10 mm, the lubrication system was improved and the ribbing was changed for better cooling.

The Horex-Columbus engine was used by a small German company Tornax on its Tornado model.

The racing version, developed on the basis of a two-cylinder engine, is worth mentioning. The maximum engine capacity for racing motorcycles with sidecar was 1 liter. To get close to the limit, the bore was increased to 80 mm, and the stroke – up to 99 mm, which provided a 995cc capacity. Cylinders were made of aluminum alloy, heads – made of bronze. The plate supporting the central main bearing was made of steel instead of aluminum to increase rigidity. This engine developed 58 hp at 7,800 rpm. There were also experiments with a compressor. In 1935, Brown and Badshin on Horex S8 became the champions of Germany in motorcycle races with a sidecar.

Parallel-twin Horex was far ahead of its time and actually became the first serial road bike with a four-stroke twin. Most people think that the British Speed Twin Triumph, which debuted only in 1937, was the first one, but this happened only thanks to a powerful PR program. While Hermann Reeb already in the 50s developed a more perfect version of his parallel-twin – Horex Imperator, which later was taken as an example by many Japanese concerns.

| Manufacturer | Horex-Columbus Werk AG, Bad Homburg, Germany |

| Years of manufacture | 1933 – 1935 |

| Quantity produced, units | 96 |

| Price | 1570 RM |

| Today’s value |

| ENGINE AND TRANSMISSION | |

| Type | Straight-twin, 4-stroke |

| Engine capacity, cc | 796 |

| Bore and stroke, mm | 75 х 90 |

| Engine rating | 30 hp at 5000 rpm |

| Sparking | Magdino |

| Carburetor | Amal 6/439, 2 units |

| Battery | 6 V |

| Clutch | Multiple-plate, oil-bath |

| Transmission | 4-speed |

| РFRAME AND WHEELBASE | |

| Frame type | Single, tubular, steel |

| Front suspension | Parallelogram |

| Rear suspension | Rigid |

| Brakes | Drum type |

| Wheel size | 3,00-19 |

| DIMENSIONS | |

| Length, mm | 2 000* |

| Width, mm | 710* |

| Height, mm | 1 100* |

| Wheelbase, mm | 1 430* |

| Ground clearance, mm | 130* |

| Seat height, mm | 700* |

| Mass, kg |

200

|

| Gas tank size, l |

|

| Maximum speed, km/h |

140

|

| Range, km | |