This entry is also available in: Russian Chinese (Traditional)

When we talk about classic American motorcycles, we immediately think about Indian and Harley-Davidson. But in the 30s, both of these brands were shadowed by the machine built by Albert “Al” Crocker.

To see this bike with your own eyes is real luck, and you won’t find another one in Russia with all your desire. Few serial motorcycles have received such legendary status as the Crocker V-twin. From 1936 to 1942 about 110 of these vehicles were built in Los Angeles, California, and each one is unique in its own way. Albert G. Crocker was known for not numbering his motorcycles, so nobody knows exactly how many bikes were built (it also says a lot about the identity of the creator himself). One thing we know for sure, that our machine was built in 1937.

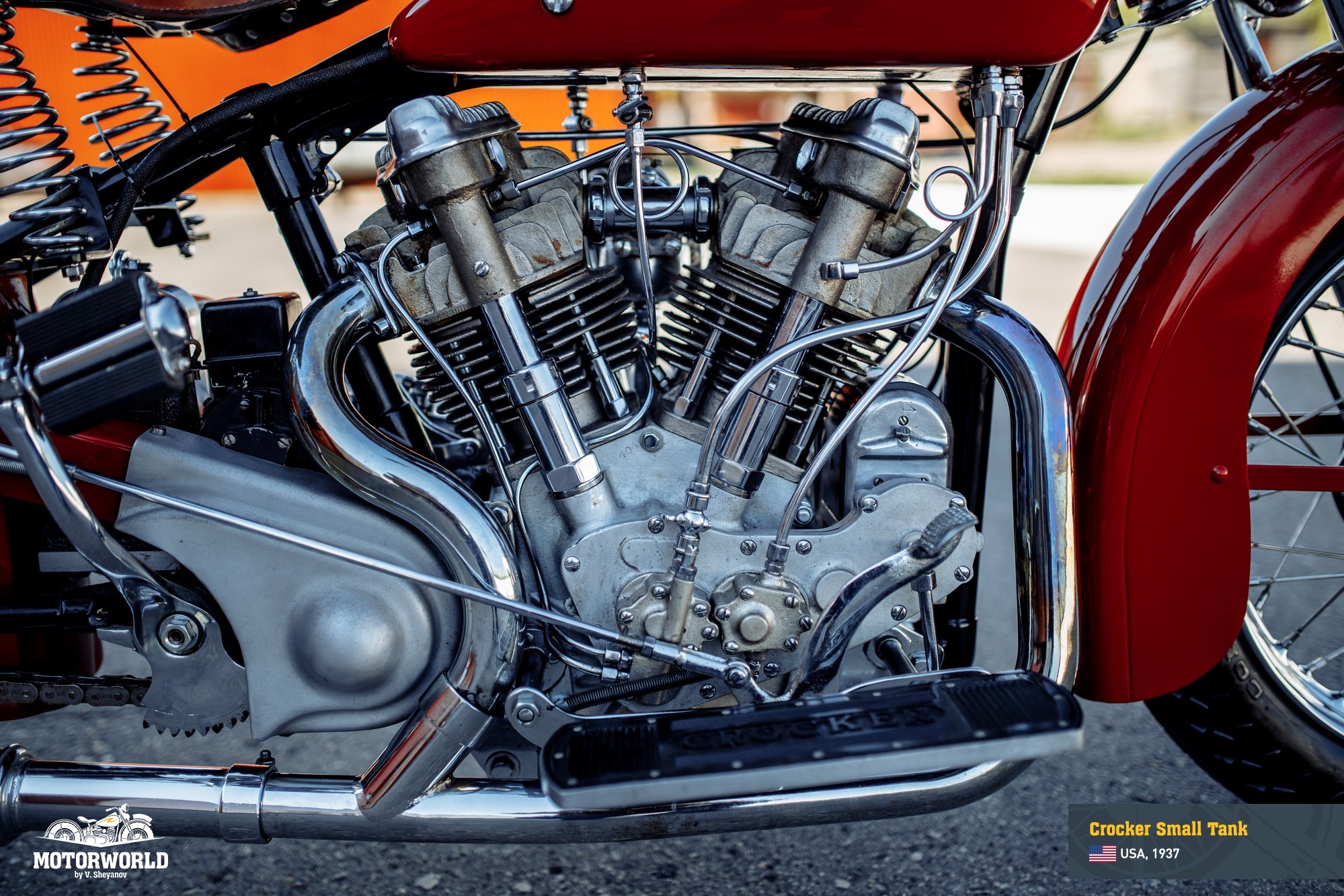

The tag 37-61-25 on the engine says that our Crocker was the 25th motorcycle made in 1937, with a 61 cubic inch (1,000 cc) engine.

Instead of concentrating on paperwork, Al Crocker focused on creating the fastest, lightest, most powerful, and most sophisticated road motorcycle. Unfortunately, his desire to use such materials and components, which at the time were used only on racing machines, was incompatible with profit-making. Forced to compete on price with such giants as Harley-Davidson and Indian, Crocker actually lost money on every machine sold, despite the direct sales, which allowed to save on dealer margin.

The losses were covered by profits from the production of high-tech equipment, and after the tragedy of Pearl Harbor, the factory switched completely to military supplies. The Crocker machines were very expensive, but for this money, the customer got a dynamic that other machine owners could only dream about. Crocker offered payments to anyone, who would lose the race to Harley-Davidson or Indian while riding his motorcycle, and they say, he never had to pay this consolation prize!

Al Crocker was born in Chicago in 1882, studied to be an engineer at a local university, and at the beginning of the XX century, he started working for the Thor motorcycle company. He soon became friends with George Hendee and Carl Hedstrom, founders of Indian, and by 1910 found himself working as a designer and engineer in the same company with them. Over time, he became interested not only in designing motorcycles but also in sales. In 1928, Crocker became a dealer of Indian in Los Angeles. There he hired a talented young engineer Paul A. Bigsby, and together they got carried away with the new-fashioned speedway racing, the new sport brought from Australia. In 1931, they began building frames for speedway bikes with a 750cc Indian Scout engine and later converting that engine to a top valve gas distribution.

Crocker’s engine was superior to Harley’s CAC but underpowered, compared to the British JAP-engine. After all, Al Crocker decided to engage in the creation of the most powerful and high-speed road motorcycle.

In 1935, Crocker sold his dealer centre and bought a small factory, where he began to make his dream come true. The first 1,000 cc Crocker V-twin appeared in 1936 – it became the first ohv American road V-twin! Harley-Davidson Knucklehead came out only a few months later.

The 45° air-cooled Crocker engine had a capacity of 986 cc (82.6mm x 92.1 mm). The rocker arms and valve springs were open and the rods went through common steel tubes. The combustion chamber was hemispherical with 90° valves and a compression ratio of 7.5.

The engine with a hemispherical combustion chamber produced 55 hp at 5,800 rpm and spun up to 6,700 rpm. Paul Bigsby, in 1936, took one of the first five motorcycles, and at the bottom of the Muroc dry lake reached 206 km/h, and that’s on a standard road vehicle!

However, after building the first 17 engines Crocker refused the hemispherical combustion chamber due to cracks in the cylinder heads and poor lubrication of rocker arms. Instead, he preferred a simple design with parallel valves and a flat combustion chamber. In addition to the reliability of good lubrication, it also provided better traction at low rpm. The machines with parallel valves were not as fast, but Crocker guaranteed maximum speed of 170 km/h. This was 10-15 km/h faster than the Indian Sport Scout or the Harley-Davidson Knucklehead.

At the same time, Crocker costs $495 against $380 for the most expensive Harley-Davidson Knucklehead modification. Moreover, Harley had four gears, while Crocker had only three. That’s why Crocker began to offer engines with an increased capacity (1,180 cc and more). Almost all components except Edison-Splitdorf magneto, Champion spark plugs, wheel rims, tires, and some other parts, Crocker made at his own factory. He even tried to make his own carburetors, until he switched to Linkert.

Unlike his transatlantic counterpart, George Brough, the creator of the so-called ‘Rolls-Royce of motorcycles’, who relied only on high-quality components to assemble his Brough Superiors, Crocker manufactured almost everything in the home.

Faced with the threat that the Crocker represented to its investment in creating the new Knucklehead, Harley is reputed to have influenced various suppliers not to meet Crocker’s orders.

Amongst these, a couple of companies were ‘persuaded’ not to sell their wire wheels to Crocker, so Crocker customers had to personally obtain their own, and ship them to Crocker for assembly into their motorcycles!

The Crocker 61ci V-twin featured generously-finned cast-iron cylinders deeply spigoted into the substantial aluminum dry-sump crankcases, and two external oil pumps – one to feed lubricant from the 2.84lt oil tank incorporated into the cast aluminum gas tank, the other to scavenge.

All bikes built had the same ultra-robust constant-mesh three-speed gearbox with a tall 3.9:1 top gear ratio. The transmission employed a four-row chain primary drive and hand-shifted via a gated rack mounted on the left of the gas tank, matched to a five-plate oil-bath clutch operated via a rocking pedal on the left floorboard.

The heavy-duty rigid frame was of a conventional diamond pattern design, while girder forks with either a single or dual spring. Crocker held the weight of his bike down to a genuine 240 kg dry – 36 kg lighter than the equivalent Harley – thanks to the liberal use of aluminum components cast in his own on-site foundry.

The Crocker looked small and compact next to its American rivals, and with a short 1,473 mm wheelbase (1,524 mm on the Big Tank model) it was much more in the mould of a British-style sporting V-twin, like the HRD-Vincent or Brough Superior, than a US bike. However, the brakes were the usual pathetically-small 178 mm single-leading-shoe drums.

While the Arizona Highway Patrol purchased a fleet of 10 Crockers in 1940 to augment their other patrol bikes, the order wasn’t enough to forestall the demise of the Crocker Motorcycle Company, and Al Crocker finally pulled the plug on motorcycle production in 1941.

Crocker hoped that Indian might buy the manufacturing rights to his bike, but the advent of the war scuppered that – a pity for everyone, except Harley-Davidson stockholders.

Together with his son Albert, Al Crocker turned his business over to manufacturing aviation parts, before passing away in 1961, at the age of 79.

Paul Bigsby went on to become a key figure in the evolution of electric guitars, creating the whammy bar and the pedal steel guitar. After founding Bigsby Guitars and selling several of his designs to Gibson and other companies, he passed away, in 1968.

The Crocker story is the great might-have-been of American biking, yet like a great vintage wine that never made it to the world’s cellar, it just withered on the vine and died.

In a 1948 interview, Al Crocker explained his bike’s demise, “It was the war,” – he said, – “We had the last 85 Crocker machines three-quarters completed, but could not get the government authorization for the critical materials to finish them. We broke them up, got $75 for the junk, and an adjustment from the government to make up for the losses. End of story.” Literally.

On the road

In spite of having no valve-lifter fitted, the bike started first kick from cold. There’s more entailed in firing up a Crocker than even the Brough Superior SS100, and still more in riding it compared to a Brit bike of the same era.

The chief challenge is adapting to the Crocker’s quite different set of controls, for while the throttle is still on the right handlebar there’s a corresponding twistgrip on the left bar that advances or retards the ignition. This is an important tool, not only for actually firing it up when you must twist it backwards to retard the ignition but also for supplementing the astoundingly poor and very definitely minuscule drum brakes on both bikes.

While the lever on the left side of the handlebar operates the front brake, your right foot works the rear one. Your left foot works the clutch via a rocking pedal, while you move the gate-mounted lever on the left of the gas tank to its rearward notch, then carefully release the clutch by pressing down with your left heel and riding the gear as your toe rises. Do that right, and you’re in business – but it takes some practice! The balanced use of the advance/retard lever, foot clutch, and throttle that’s needed to guide the Crocker through traffic is truly an acquired skill, though, of course, city streets weren’t its natural habitat – the Crocker was a king of the open road.

The Crocker’s V-twin engine sounds glorious, it’s like the sound of thunder, barely-muffled exhausts, and it’s also pretty well balanced – it’s smoother than other American vintage-era V-twins. I didn’t have space to really give her the berries, but by all accounts, this was a genuinely impressive ton-up motorcycle that would have been a fine match for the Brough Superior. Too bad no Crockers ever found their way to British shores in the period – I’m sure they would have given a good account of themselves at Brooklands.

There’s a treat in store for the fortunate new owner of this Crocker. The Crocker 61ci V-twin was a true original. American excellence on two wheels, the Crocker represents a landmark in Trans-Atlantic motorcycle design, just as Phil Irving’s HRD-Vincent and George Brough’s eponymous Superiors did on the other side of the pond, at exactly the same time.

Based on the Alan Catchcart’s story.

Crocker Small Tank Specs

| Manufacturer | Crocker Motorcycle Company |

| Years of manufacture | 1936-1940 |

| Quantity produced, units | 110 |

| Price | |

| Today’s value |

| ENGINE AND TRANSMISSION | |

| Type | V-Twin |

| Engine capacity, cc | 1000 |

| Bore and stroke, mm | 82.55×92 (bore 3¼ , stroke 3 5/8”) |

| Engine rating | 60 hp |

| Ignition | |

| Carburetion | |

| Electrics | |

| Clutch | |

| Transmission | Constant mesh type |

| FRAME AND WHEELBASE | |

| Frame | |

| Front suspension | |

| Rear suspension | |

| Brakes | |

| Wheel size | |

| DIMENSIONS | |

| Length, mm | |

| Width, mm | |

| Height, mm | |

| Wheelbase, mm | |

| Ground clearance, mm | |

| Seat height, mm | |

| Mass, kg | |

| Fuel, ltr | |

| Top speed, km/h | |

| Range, km | |